Energy efficiency case study

Introduction

A warehouse is looking to provide flexibility services to SP Electricity North West through a Peak Reduction contract by implementing energy efficiency measures to reduce its demand, providing additional capacity to help manage network constraints.

About flexibility services

When the demand for electricity is greater than the amount that SP Electricity North West can provide, we procure flexibility services to alleviate constraints on our network during peak times. These services are provided by companies or individual customers known as flexibility service providers (FSPs) who own assets in our region such as generators, battery storage and electric vehicle (EV) charge points. FSPs should be able to generate more, or use less, electricity during a pre-agreed service delivery window, and provide at least 10kW of flexibility capacity either individually or via an aggregator. This allows us to balance supply and demand, ensuring a safe and reliable supply of energy for our customers. In return for providing extra capacity, FSPs receive payment from SP Electricity North West.

Delivering a Peak Reduction service via energy efficiency measures

Participants can bid for multiple years of service by installing energy-saving measures. There are a number of energy efficiency measures that the warehouse can implement to reduce its electricity consumption. These include:

Lighting: Lighting accounts for between 65% and 95% of energy use in ambient warehousing. There are many simple and inexpensive ways to reduce lighting energy consumption and costs while maintaining adequate light levels:

- Switching to LED lightbulbs: There are two main types of energy efficient light bulbs available in the UK. Compact fluorescent lamps (CFLs) and light emitting diodes (LEDs). CFLs use 60%-80% less energy than traditional incandescent light bulbs but LEDs use 90% less. So while both are cost effective, LEDs are the most energy-efficient option. Originally the cost of LED lighting was comparatively high but prices have come down a lot over the last few years, meaning this option now offers the best value for money. Replacing a single halogen light bulb with an LED of the same brightness will save you up to £2 per year.

- Turning off lighting: Turn off lighting in unoccupied areas or when sufficient natural daylight is present.

- Utilising occupancy sensors: Lights are automatically turned on when there is somebody there and are turned off after a period of vacancy. Sensors can achieve savings of 30% or more on lighting costs and can be zoned by aisle or area depending on the individual requirements of the warehouse.

Improving insulation: The standard of building insulation and building air-tightness should be prioritised. Spray foam insulation provides effective insulation that seals the roof from the interior. This type of application adheres to virtually any surface at any angle, and is especially effective in a warehouse environment where corrugated roofing is typical. Traditional insulators cannot follow the contours of corrugations - they are therefore complex to install and may create gaps which can result in condensation. The benefits of insulating a warehouse soon add up: greater temperature control and energy savings; a warmer environment in the winter and a cooler one in the summer and the eliminatiion of draughts and leaks.

Installing solar photovoltaic (PV) panels: Solar PVs generate electricity by absorbing sunlight with PV cells in the panel. Solar panels can still work on cloudy days, but not always at their peak performance. With large available expanses of roof area, warehouses are an ideal location to install PV solutions. As warehouses are energy-intensive buildings, installing a solar PV system on the roof provides a secure and reliable source of renewable energy that can be used to generate electricity for the entire building, reducing electricity demands from the network. It also reduces the carbon footprint of your business and provides extra revenue when used to generate electricity for the purpose of providing flexibility services to the network (under an Operational Utilisation & Variable Availability or Operation Utilisation (generation turn up) product).

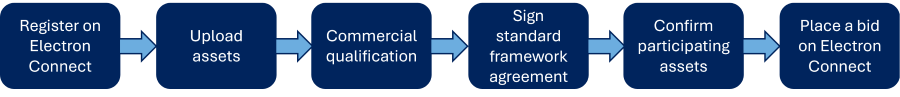

Pre-tender

Our tenders are published on the ElectronConnect platform twice a year in spring and autumn in line with our Network Development Plan (NDP) and Distribution Future Electricity Scenarios (DFES) publications to reflect our latest network requirements. To be notified of our upcoming tenders, the warehouse signs up to our flexibility mailing list.

Before the launch of the tender, the warehouse:

- Registers the company on ElectronConnect to pre-qualify to participate. The information submitted such as credit checks and insurance details is assessed by SP Electricity North West. Once approved, the company's commercial qualification remains valid for future tender rounds.

- SP Electricity North West utilises the framework style Standard Flexibility Services Agreement developed by the Energy Networks Association Open Networks Project. The warehouse can sign up to the general T&Cs of this agreement as part of commercial qualification, and a signed copy must be returned via Electron before placing a bid.

- Registers its asset(s) on ElectronConnect.

Tender process

Pre-qualification

Once the Invitation to Tender (ITT) has been published, the warehouse reviews the requirements using the map included in our latest flexibility service requirement. Once it has established that the warehouse is located within a requirement zone seeking a Peak Reduction service, it calculates how much of the required demand response it can offer, when, and at what price. Before submitting a bid, the warehouse uses the cost calculator tool on our website to check that the prices it is prepared to offer for availability and utilisation don't exceed the ceiling price that we are offering for the service as part of this tender round. The cost calculator can be found in the ITT appendices for our latest flexibility services requirement. At this point, the warehouse decides it would like to participate in the tender.

The next step for the warehouse is to complete technical qualification on ElectronConnect by confirming the assets it wishes to put forward in the competition. SP Electricity North West then assesses the technical details of the participating assets and the capability for delivery. If the warehouse is unable to provide 10kW of flexible capacity, it can still take part via an aggregator. Aggregators such as electricity suppliers combine load from multiple customers to provide flexibility services; this is explained in more detail in our homeowner case studies on Peak Reduction and Scheduled Utilisation. The warehouse is notified via ElectronConnect that its assets meet the requirements of this tender, allowing it to move to the bidding stage of the process.

Submitting a bid

For the final stage of the procurement process, the warehouse submits a bid to the tender on ElectronConnect. This is done by linking the pre-registered assets to the peak reduction payments, as well as the periods where the warehouse can commit to reduce its demand peaks. Once the bidding window has closed, SP Electricity North West assesses the tender responses before accepting or rejecting bids based on the proposed payment and the asset's ability to meet the specification. If the warehouse's bids are successful, it will enter into a flexibility services agreement with SP Electricity North West to deliver the peak reduction service within the required service windows.

Helpful tips to consider before submitting a bid

- When calculating the tender bid prices the provider should consider the cost of lost revenue, fuel costs, environmental or permit fees, initial set-up costs, maintenance, other revenue streams available, energy savings benefits etc.

- When thinking about utilisation periods the provider should consider the practicalities of these periods, the processes required to ensure that the service can be delivered, seasonal considerations e.g. major televised events, Christmas period, weather-related issues e.g. extreme cold weather increasing heating demand and maintenance periods.

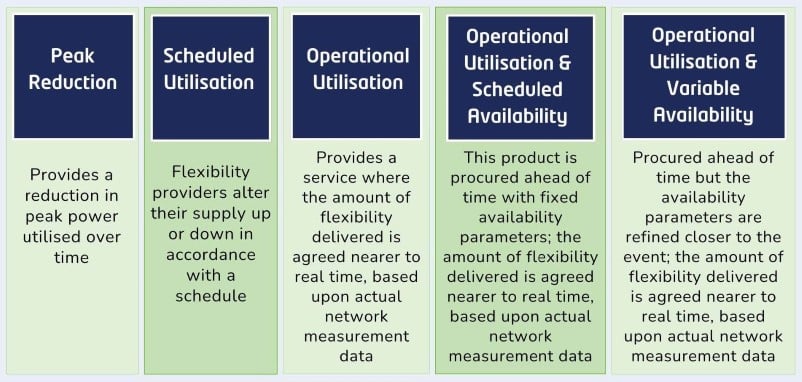

Flexibility service products

SP Electricity North West procures four common products (services), which align with the Open Networks service definitions:

- Peak Reduction

- Scheduled Utilisation

- Operational Utilisation

- Operational Utilisation & Variable Availability.

The Peak Reduction product is a pre-fault product that seeks a reduction in peak power used over time. Providers of this service are required to keep their peak demand below a pre-defined threshold during pre-agreed service windows. This product could be used where energy efficiency measures are planned that would reduce a site’s overall electricity consumption across the year but specifically during high peak periods.

The warehouse will reduce its electricity demand to provide additional capacity to SP Electricity North West by implementing energy efficiency measures in the building. As these requirements are predictable, they are declared at the contracting stage, allowing the warehouse sufficient time to implement the energy efficiency measures ahead of the required delivery service period.

Dispatch

SP Electricity North West will not provide a dispatch command. It is expected that the utilisation of energy efficiency measures will provide an enduring reduction in the warehouse’s demand.

Worked example

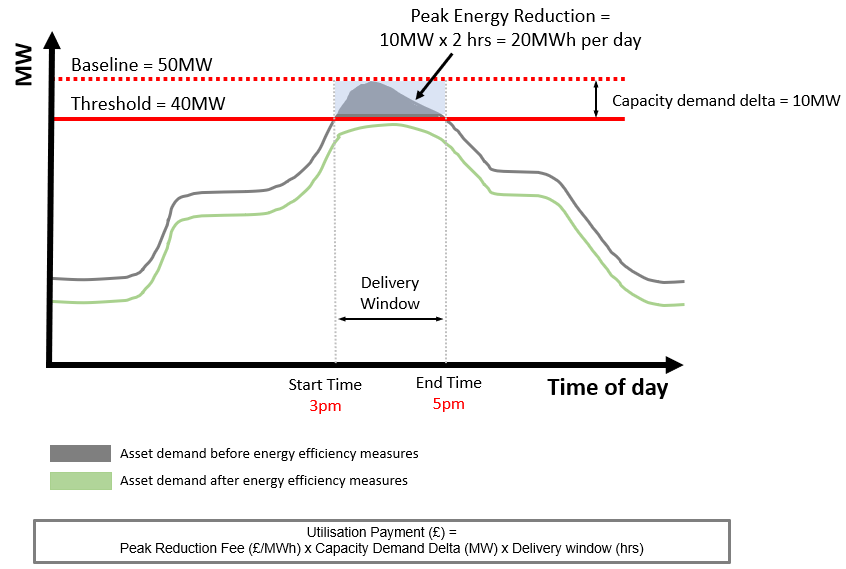

The warehouse has a peak demand of 50MW and has implemented energy efficiency measures which have reduced its peak load to 40MW. The warehouse has signed a Peak Reduction service (energy efficiency) contract with SP Electricity North West under which it is required to keep its demand below 40MW between 3pm and 5pm every day between November and March.

Baselining

A baseline is a reference used to measure the amount of flexible capacity delivered to the network by FSPs. There are different kinds of baselining methodologies used depending on the type of asset and service being provided. Examples of these include historical baselines (using past meter readings to estimate the baseline using standard algorithms) and nominated baselines (using other forecasting techniques such as weather-based models to estimate the future baseline).

The baseline for energy efficiency measures will be determined by their historical demand profile with adjustments for other known changes in the site usage and external factors e.g weather. Following the required service delivery period, SP Electricity North West will verify that the energy efficiency measures carried out by the warehouse delivered the necessary energy reductions required during these periods. By participating in flexibility services, the warehouse will be reducing the predicted network constraints, allowing us to defer reinforcement.

Invoicing

Subject to the delivery of flexibility services, the warehouse will invoice SP Electricity North West and will receive payment by bulk electronic clearing (BACS) by the end of each quarter (after the invoice is received). More details on payment can be found in the terms and conditions of each Invitation to Tender.

Useful links

Register for updates

Sign up to our flexibility services mailing list to find out about new requirements and receive invites to our events.

Get in touch

If you would like to leave feedback, book a meeting with a member of our team or if you have any questions about flexibility services, please get in touch.

Energy efficiency for business

Find out how to make your workplace more energy efficient.